Technical Textiles - German Engineering since 1722

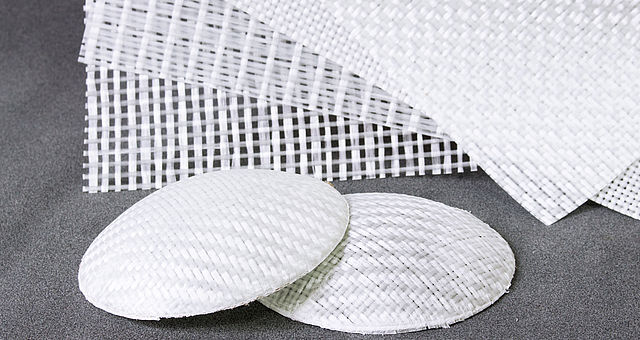

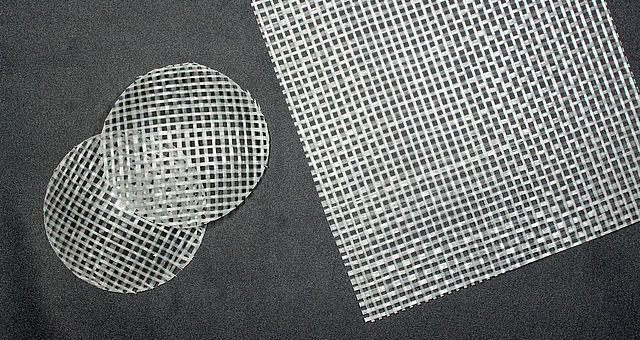

THERMOPLASTIC PREPREGS (GLASS FIBER PREPREGS/ARAMID PREPREGS) - PRE-IMPREGNATED TEXTILE FIBER-MATRIX SEMI-FINISHED PRODUCTS

Demands for materials in the manufacturing industry are high. Regardless of the industry, they should be sturdy and lightweight, as well as cost-efficient. Prepregs are available with thermosetting and thermoplastic coatings. Composite materials made of continuous fibers coated with thermoplastic matrix materials offer numerous advantages.

Advantages of thermoplastic prepregs over thermosetting ones:

- Not REACH-critical

- Recyclable

- Weight reduction

- Extreme rigidity/strength

- Solvent-resistant

- Thermally formable

- Drapable

- Weldable

COMPETITIVE ADVANTAGES WITH OUR ENDLESS FIBER REINFORCED COMPOSITE DELICOMP®

Our thermoplastic prepreg DeliComp® optimizes your production processes sustainably, no matter where our composite is used: automotive, lightweight components, ballistic applications, construction sector, or other industries. Thanks to various textile substrate materials with a specially developed matrix, this composite semi-finished product offers a wide range of applications. It can be used as an insert in injection molding or for laminating other materials, allowing the use of nearly all available yarns and rovings on the market.

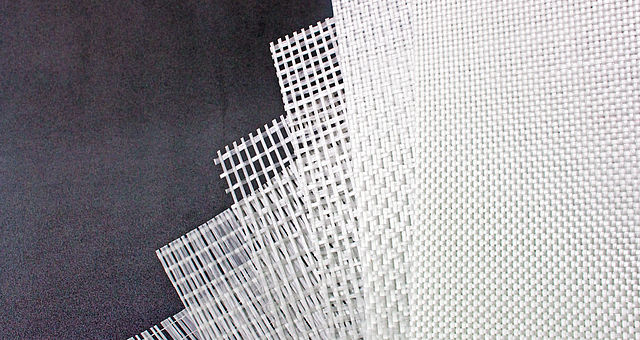

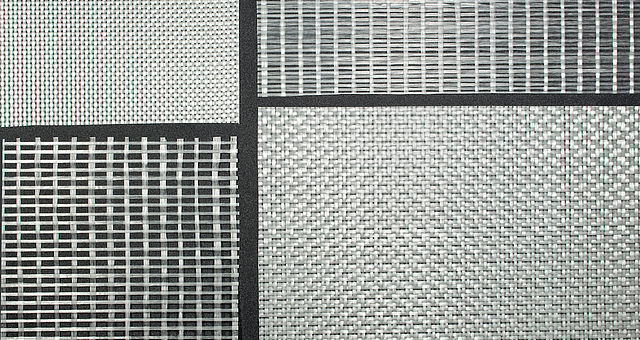

In our manufacturing process, we use high-strength yarns like glass rovings, aramid yarns, or basalt filaments, which are fully impregnated in the desired matrix, such as polypropylene, after the weaving process. Thanks to the small size of the dispersed plastic particles, they can be gently introduced into the textile during our special infusion process at low pressure. The advantage is that the textile fiber orientation remains very well-preserved, and all individual fibers are encapsulated by the matrix. The delicate fabric becomes manageable without shifting, even with open lattice structures.

Our thermoplastic prepreg is available in various roll formats, from coarse, open lattice to dense, closed structures. Upon request, we also manufacture custom-cut geometries and deliver them worldwide on time. DeliComp® comes in various forms, including lattice, unidirectional fabrics, and full-surface fabrics.

Download Flyer DeliComp®Here you can learn more about DeliComp® laser cutting - directly from our partner eurolaser GmbH.

PREPREG PROCESSING AT YOUR FACILITY

Because our thermoplastic prepreg DeliComp® is significantly thinner and more flexible than typical thermoplastic sheets, it can be easily formed into the desired contour with the closing injection molding mold. It can also be laminated. It fills the performance gap between pure injection-molded parts (with glass fiber content) and often oversized components with thermoplastic sheet inserts.

Depending on the geometry and the DeliComp® variant used, the otherwise necessary preheating process can be completely eliminated. The energy from the injected plastic melt is sufficient to melt the DeliComp® matrix and create a composite. This offers significant cost reduction potential for injection molding.

Applications include:

- Structural reinforcement

- Fragmentation protection

- Lightweight components: surface

- Reinforcement

- Substitution of metal inserts in plastic parts

DON'T SETTLE FOR THE "STATE OF THE ART," CHOOSE SOLUTIONS THAT "IMPROVE" THE CENTRAL STAGES OF YOUR VALUE CHAIN SUSTAINABLY

Compared to the state of the art, such as injection molding with glass fiber content, thermoplastic sheets, and thermosetting processes, our thermoplastic prepreg offers numerous advantages:

- Slide-resistant and easy to handle

- Highly processable in the injection molding process

- Process with short cycle times and high economic potential

- Compared to "normal" injection-molded components (with/without glass fiber content), an insert made of DeliComp® improves mechanical performance (tensile/impact strength, fracture behavior)

- Closes the performance gap between thermoplastic sheet reinforcement and conventional injection molding

- Significant weight reduction in the component

- 100% recyclable

- Good laser cutting capability

The fabrics can consist of 100% of one type of yarn, but hybrid fabrics are also possible. Yarn thicknesses are variable and can be adjusted to suit the applications. In addition to the known PP matrix, other matrix systems such as PA can be used based on customer requirements.

Benefits of DeliComp® at a glance:

- Reduction of process steps

- Lower energy consumption during thermoforming

- Cost reduction

- Weight reduction

- Consistent ratio of fiber and matrix

- Flexible and easy shaping

- Increased tensile strength

- Increased impact resistance

- Improved fracture behavior

- Consistent dimensional stability and thickness

Your contact at Delcotex for DeliComp®:

Ansgar Benölken

Phone: 0521 543-505

E-mail: ansgar.benoelken@delcotex.de

Bio-Composite

Development and production of sustainable fibre-metal laminates (FML) based on natural and recyclable raw materials.

Learn more about our bio-composite here