Technical Textiles - German Engineering since 1722

Backing fabrics

There are different types of backing fabrics for various purposes:

Backing fabrics – washed out, heat-set and calandered

The advantages of DELCOTEX backing fabrics:

- high-quality surfaces

- perfect adhesion

- problemfree coating processes

The outstanding properties of our loom state technical fabric are complemented, if desired, with various finishings:

- removal of spin finishes and sizing operations

- realisation of extremely low residual grease < 0,1 %

- shrinkage and thermal homoginization

- ideal preperation for subsequent dying or printing processes

- considerable improvement of adhesion

Almost limitless properties profile:

- fabric widths up to 520 cm

- fabric density from 30 - 1500 g/m²

- yarn counts from 10 dtex - 5500 dtex, multi-/monofilament

- cutting cold/hot/ultrasonic

- piece lengths several meters wihout a seam

- 100% optical merchandise evaluation

- error log in 3 languages if desired

- perfectly stress-optimized roll winding

- packaging on cardboard tubes, steel core, etc.

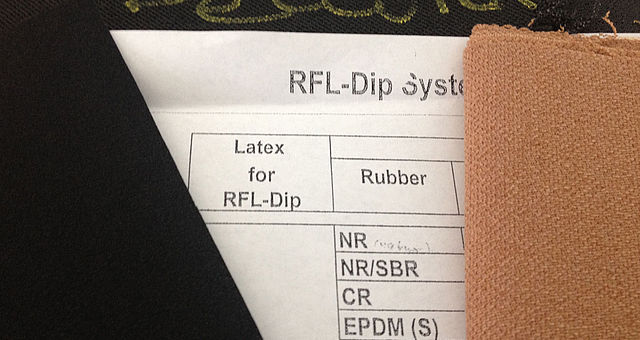

With Coupling systems for rubberization

Perfect adhesion, long service life, low material fatigue. We realize the perfect coordination of the carrier fabric with the rubber coating process of our customers.

Property profile almost without limits:

- fabric widths up to 520 cm

- fabric weights from 30 - 1500 g/m²

- fabric made of polyester, polyamide, viscose, aramid, ...

- with adhesion promoters based on RFL-Dip (NR, NR/SBR, CR, EPDM,....)

- roll lengths individual

- presentation on cardboard sleeves, wooden trees, steel cores, docks, etc.

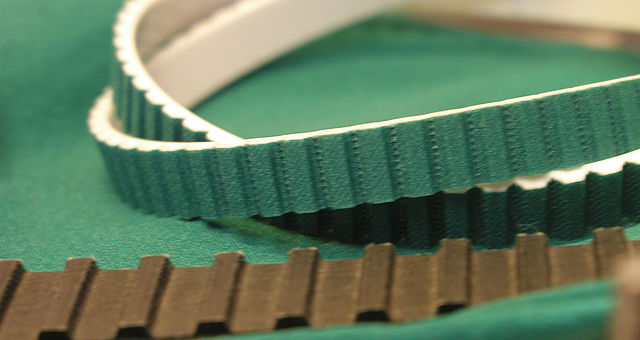

for industrial timing belts

Reliable, high power transmission and high running smoothness, in addition to high dynamicstrain; practically unimaginable without stretch fabric. Stretch fabrics (warp and weft direction) by DELCOTEX supply optimal power transmission for drive belts and timing belts and guarantee longevity. The combination of meticulously selected yarn with a suitable finishing generate the stretchiness that is required for drive and timing belts. We offer stretchy fabrics with adhesives made out of CR, NBR, SBR, XNBR,...

Application examples and possibilities for stretchy fabric by DELCOTEX:

- stretch fabric with adhesive for rubber industrial timing belts

- transverse stretchy fabric up to 150 cm width

- lenghtwise stretchy fabric up to 250 cm width

- multilayered stretchy fabric up to 3,5 mm thick

- bi-stretch fabric

- antistatic stretchy fabric

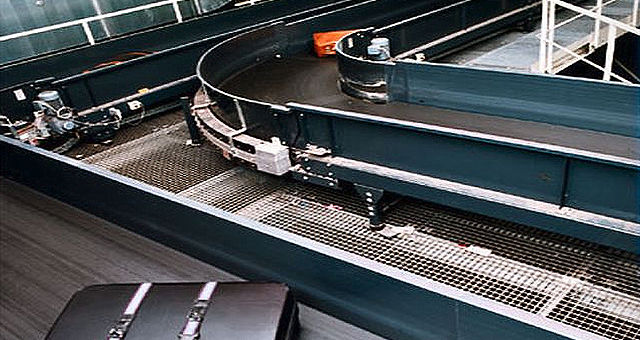

for conveyor belts

Perfect surfaces, optimum transportation effects, a stable forward movement, anti-static properties are possible with conveyor belt fabrics from DELCOTEX.

- warp yarns with and without active adhesion

- interwined with steel or carbon fibres

- low shrinkage monofil weft yarn

- warping machines with thread breaking supervision and permanent tension control

- the most modern rapier looms up to 520 cm to achieve loop-free cloth

- on-loom fabric inspection

- final cloth inspection with perfect winding

Fabric properties almost without limits:

- fabrics out of polyester, polyamide, aramide, ...

- monofil yarns, multi-fil yarns and spun fibres

- fabric weights up to 1.500 g/m²

- fabric widths up to 520 cm

- single and multilayer fabrics

- loomstate or thermofixed